Description

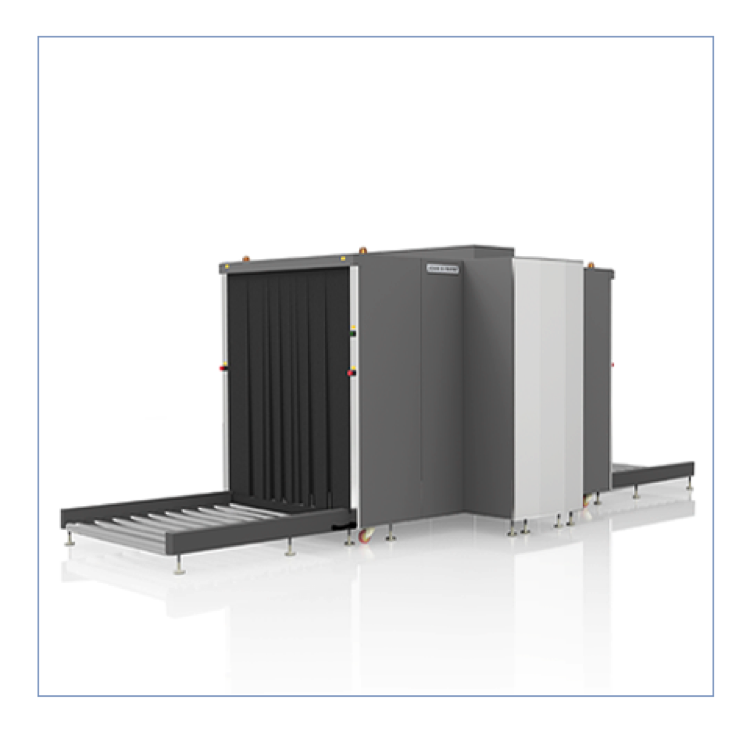

The ADANI BV 160180 device has been designed as an effective and innovative solution for visual inspection of small palletized cargo loads up to 3000 kg.

The X-ray inspection system BV 160180 is designed to carry out visual inspections of medium palletized loads (up to 3000 kg) and to detect threats and prohibited items. The system complies with the requirements of customs services, warehouses, transport operators, carriers, courier companies and airports. This x-ray inspection system is the best security solution for the inspection of small and medium-sized loads transported on standard low-stack pallets. Low X-ray conveyor facilitates loading and unloading of cargo and goods.

The ADANI BV 160180 X-ray Luggage Scanner operates to detect weapons, explosives (including plastic explosives), drugs, detonators and dangerous items posing a threat to security. It is a very effective and reliable safety equipment.

Dual energy imaging technology offers automatic color coding of materials with different atomic numbers. This helps operators identify suspicious items and prevent hazards, and avoids the need for repeated scans and time-consuming unpacking of loads and packages.

This efficient system has been designed to reduce inspection time and ensure proper image quality. The BV 160180 easily integrates into any operating process in place.

CONFIGURATION

- Device body

- Frame

- carrier

- Inspection tunnel

- Distribution panel

- Digital X-ray image receiver

- Sensitive digital X-ray detector

- Electronic interface unit

- X-ray unit

- X-ray generator

- The collimator

Other

- Operator workstation

- A set of control programs

- Set of spare parts, tools and equipment

- Operational documentation

- Package

- Options

- Input / output rollers

- Operator panel

- A set of test objects

- Ramp

- Application:

- Palletized cargo

- Package loan

- Small cargo loads

- Key Features:

- High efficiency / ability

- Multi-functionality in use

- Automatic color coding

- Stock on the conveyor up to 3000 kg

- Power generator

Technical parameters

| Dimensions | 6800 x 2720 x 2350 mm [267.71 x 107.09” x 92.52”] |

| Tunel dimensions | 1750 x 1800 mm [68.90” x 70.87”] |

| Scanning speed | 0.22 ± 0.03 |

| Max load | 3000 kg [6613 lbs] |

| Weight | 2970 kg [6547 lbs] |

| Hight of the carrier | 300 mm [11.81”] |

| Type of detector | Double energy |

| Work temperature | +10º – +35ºC |

Picture quality

| Steel penetration | 34 mm [1.33”] |

| Detection capability, AWG | 35 |

| Number of colors | 4 |

X-ray

| Anode voltage, kV | 200 |

| Radiation angle | 70° |

| Cooling system | oil bath |

| Anode type | stationary |

Features / functions of the software

The purpose of this system software is to control the operation of the scanner as well as to ensure the production, visualization and processing of digital x-ray images. A control panel is available to facilitate the operator’s work. This panel provides access to all software functions.

General Purpose Features:

Login based on password

Self-test and performance support features:

- Automatic self-test

- Display messages about the status of the scanner operation

- Warming up of the x-ray generator (the process can be started both manually and automatically)

Equipment control functions:

- Control of the belt conveyor drive, safety shutter drive, X-ray generator

- Automatic change of the generator operation mode depending on the scanner idle time

- Data acquisition from an X-ray detector

- Automatic calibration of the x-ray detector

- Emergency shutdown of the x-ray generator

- Indication of X-ray activity

Digital Image Acquisition, Visualization and Processing:

- Image acquisition without additional algorithmic processing

- Emphasizing / enhancing the presence of optically dense objects

- Adjustment – contrast, highly absorbent objects

- Inverting images

- Perform gamma correction of images

- Overall contrast optimization: combination of edge enhancement and local contrast enhancement algorithms

- Coloring pictures according to the calculated values of the atomic numbers of the substances that make up the objects subjected to control activities

- Giving colors to substances with atomic numbers in the selected range

- Pseudo-coloring of objects with a choice of different palettes

- Showing organic objects with atomic numbers equal to 7, 8 and 9

- Showing substances according to the selected signal strength range

- Magnify one of the nine predefined image areas

- Magnify images up to 96x

- Automatically highlight / identify suspicious objects (which may be associated with drugs, explosives or weapons)

Additional functions:

Saving X-ray images to files

Storage of a predefined number of images

Viewing the image archive

Copying images to external media (CD / DVD disks and flash drives)

Browse and copy images from the local network

Automatic service reports – preparation, archiving and printing

Operator efficiency quality control – with the TIP program module

Counting checked luggage