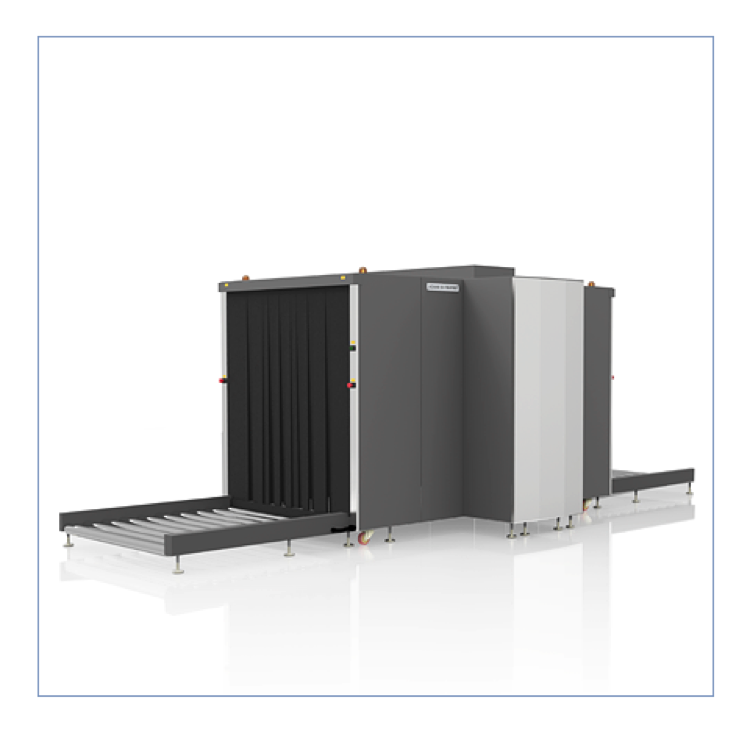

BV 160165

BV 160165 / BV 160180 X-ray inspection system is the best combination of minimal footprint and high throughput. The X-ray machine is designed for the inspection of pallets and large cargo weighing up to 3000 kgs (6600 lbs.)

Due to the system’s small footprint, it can be easily integrated into existing security infrastructure.

The automatic highlighting of suspicious objects helps the operators identify threats and avoid the necessity of hand inspections.

The system’s Dual Energy imaging and the automatic color coding of materials with different atomic numbers simplifies the process of image analysis and the detection of potential threats and safety hazards such as narcotics, firearms and weapons, explosives (including plastic explosives), and smuggled goods.

KEY FEATURES

| Oversize dimension of the tunnel | BV 160165 / BV 160180 tunnel makes it possible to scan air transport containers and palletized cargo. |

| Increased load capacity | Chain-driven robust rollers provide fabulous capacity of the conveyor which is 3.000 kg of spreaded load. |

| Automatic identification of suspicious objects (drugs, explosives) and highlighting of optically dense objects | Algorithms used in software enable automatic highlighting of such objects as weapons, explosives, narcotics, as well as opaque areas, where dangerous object may be concealed.These functions improve operating efficiency. |

| Multilanguage interface | Including English, German, Russian, Italian, French, Spanish, Portuguese, Polish, Arabic, Chinese and any other language on request. |

| User friendly interface | The set of self-intuitive tools and settings make it possible for the operator to master the system control quickly and easily making thus his/her daily work more comfortable. |

| Real-time self-diagnostics | State of all important assemblies and components is controlled in the on-line mode allowing the system to be kept operational and the operator to be informed about any changes in good time. |

| Availability 7 and 3 colors imaging | Operator is free to choose whether to use 3 colours imaging (organics/inorganics/metals), which is familiar by experience, or 7 colours imaging, which is more detailed one and which enables material discrimination on effective atomic number more precisely. New colours help the operator to stay attentive and his/her perception to remain not “overloaded” when working during a long period of time. This improves the performance quality of the operator and a through-flow rate of inspection points. |